EXPLORING THE USE OF RICE HUSK PROCESSING BYPRODUCTS IN COMPOSITE SUPERABSORBENT MATERIAL SYNTHESIS

UDC 544.773.432

Abstract

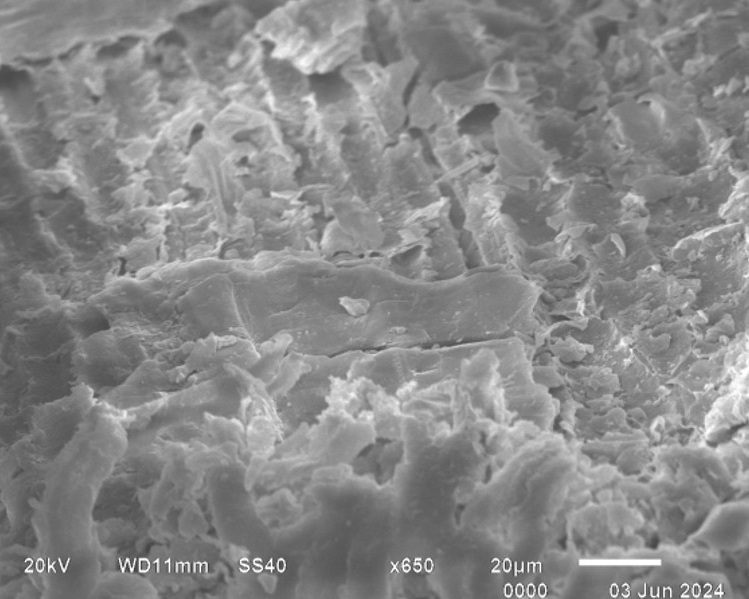

Rice husk, a byproduct of rice grain cleaning, is an agricultural waste rich in polysaccharide and silicon fractions. Its disposal through burning harms the environment and results in the loss of a valuable raw material for producing various chemical technology products. This study aimed to synthesize composite superabsorbents from the carboxymethylated polysaccharide fraction of rice husk and to evaluate the water absorption characteristics of the resulting polymers. The polysaccharide fraction was extracted through sequential acid and alkaline hydrolysis, followed by carboxymethylation to enhance water solubility. The synthesized products were characterized using FTIR spectroscopy and scanning electron microscopy. The carboxymethylated rice husk derivative was utilized in the synthesis of composite superabsorbents, which demonstrated water-absorbing properties comparable to those of commercial carboxymethyl cellulose. Notably, these superabsorbents exceeded commercially available samples in terms of water absorption performance. An analysis of the swelling behavior of the synthesized superabsorbents revealed that the process is governed by chemisorption. It was observed that water molecule diffusion within the polymer matrix occurred at a slower rate compared to samples derived from commercial carboxymethyl cellulose. These findings highlight the potential of rice husk-derived materials as promising components for the synthesis of composite superabsorbents.

Downloads

References

Zelenskiy G.L. Ris: biologicheskiye osnovy selektsii i agrotekhniki. [Rice: biological foundations of selection and agri-cultural technology]. Krasnodar, 2016, 238 p. (in Russ.).

Sergiyenko V.I., Zemnukhova L.A., Yegorov A.G., Shkorina Ye.D., Vasilyuk N.S. Zhurnal Rossiyskogo khimich-eskogo obshchestva im. D.I. Mendeleyeva, 2004, vol. 53, no. 3, pp. 116–124. (in Russ.).

Zohuriaan M., Kabiri K. Iran. Polymer Journal, 2008, vol. 17 (6), pp. 451–477.

Bashari A., Rouhani Shirvan A., Shakeri M. Polym. Adv. Technol., 2018, vol. 29, no. 12, pp. 2853–2867. https://doi.org/10.1002/pat.4290.

Sannino A., Demitry C., Madaghiele M. Materials, 2009, vol. 2, no. 2, pp. 353–373. https://doi.org/10.3390/ma2020353.

Dabhi R., Bhatt N., Pandit B. Int. J. Eng. Res., 2014, vol. 3, pp. 1402–1406.

Sorokin A., Sukhanov P., Popov V., Kannykin S., Lavlinskaya M. Cellulose, 2022, vol. 29, no. 1, pp. 159–173. https://doi.org/10.1007/s10570-021-04326-3.

Buchholz F.L., Graham A.T. Modern superabsorbent polymer technology. New York: Wiley-VCH, 1998, 279 p. https://doi.org/10.5860/choice.35-5664

Po R. Journal of Macromolecular Science, Part C: Polymer Reviews, 1994, vol. 34, no. 4, pp. 607–662. https://doi.org/10.1080/15321799408014168.

Zhang J., Wang A. React. Funct. Polym., 2007, vol. 67, no. 8, pp. 737–745. https://doi.org/10.1016/j.reactfunctpolym.2007.05.001.

Rashidzadeh A., Olad A. Carbohydr. Polym., 2014, vol. 114, pp. 269–278. https://doi.org/10.1016/j.carbpol.2014.08.010.

Guilherme M., Aouada F., Fajardo A., Martins A., Paulino A., Davi M., Rubira A., Muniz E. European Polymer Journal, 2015, vol. 72, pp. 365–385. https://doi.org/10.1016/j.eurpolymj.2015.04.017.

Klinpituksa P., Kosiyakanon P. Int. J. Polym. Sci., 2017, vol. 2017, pp. 1–6. https://doi.org/10.1155/2017/3476921.

Raju K.M., Raju M.P., Mohan Y.M. J. Appl. Polym. Sci., 2002, vol. 85, no. 8, pp. 1795–1801. https://doi.org/10.1002/app.10731.

Behera S., Mahanwar P.A. Polym.-Plast. Technol. Mater., 2020, vol. 59, no. 4, pp. 341–356. https://doi.org/10.1080/25740881.2019.1647239.

Drury J.L., Mooney D.J. Biomaterials, 2003, vol. 24, no. 24, pp. 4337–4351. https://doi.org/10.1016/S0142-9612(03)00340-5.

Lee W., Lin Y. J. Appl. Polym. Sci., 2001, vol. 81, no. 6, pp. 1360–1371. https://doi.org/10.1002/app.1561.

Bajpai S.K., Bajpai M., Sharma L. Des. Monomers Polym., 2007, vol. 10, no. 2, pp. 181–192. https://doi.org/10.1163/156855507780378285.

Barana D., Salanti A., Orlandi M., Ali S., Luca Z. Ind. Crop. Prod., 2016, vol. 86, pp. 31–39. https://doi.org/10.1016/j.indcrop.2016.03.029.

Nafo N., Zenitova L., Prosvirnikov D., Safin R. Systems. Methods. Technologies, 2019, vol. 3(43), pp. 122–128. https://doi.org/10.18324/2077-5415-2019-3-122-128.

Chen S.-C., Wu Y.-C., Mi F.-L., Lin Y.-H., Yu L.-C., Sung H.-W. Journal of Controlled Release, 2004, vol. 96, no. 2, pp. 285–300. https://doi.org/10.1016/j.jconrel.2004.02.002.

Revellame E., Fortela D., Sharp W., Hernandez R., Zappi M. Cleaner Engineering and Technology, 2020, vol. 1, 100032. https://doi.org/10.1016/j.clet.2020.100032.

Ho S.Y., McKay G. Process biochemistry, 1999, vol. 34, no. 5, pp. 451–465. https://doi.org/10.1016/S0032-9592(98)00112-5.

Peppas N.A., Khare A.R. Advanced drug delivery reviews, 1993, vol. 11, no. 1-2, pp. 1–35. https://doi.org/10.1016/0169-409X(93)90025-Y.

Kostryukov S.G., Malov N.A., Matyakubov Kh.B., Konushkin I.A. Vestnik Permskogo universiteta. Seriya «Khimi-ya», 2022, vol. 12, no. 1, pp. 5–16. https://doi.org/10.17072/2223-1838-2022-1-5-16. (in Russ.).

Reznikov V.M., Sorokina N.F. Obshchaya i prikladnaya khimiya, 1972, no. 4, pp. 107–115. (in Russ.).

Kazitsyna L.A., Kupletskaya N.B. Primeneniye IK-, UF-, YAMR-spektroskopii v organicheskoy khimii: ucheb. posob. dlya vuzov. [Application of IR, UV, NMR spectroscopy in organic chemistry: textbook for universities]. Moscow, 1971, 264 p. (in Russ.).

Shipina O.T., Garayeva M.R., Aleksandrov A.A. Vestnik Kazanskogo tekhnologicheskogo universiteta, 2009, no. 6, pp. 148–151. (in Russ.).

Zarubina A.N., Ivankin A.N., Kuleznev A.S., Kochetkov A.S. Lesnoy vestnik, 2019, vol. 23, no. 5, pp. 116–125. https://doi.org/10.18698/2542-1468-2019-5-116-125. (in Russ.).

Murashkevich A.N., Lavlinskaya A.S., Barannikova T.I., Zharskiy I.M. Zhurnal prikladnaya spektroskopiya, 2008, vol. 75, no. 5, pp. 724–728. (in Russ.).

Markin V.I., Bazarnova N.G., Karpova Ye.V., Skvortsov Ye.V. Khimiya rastitel'nogo syr'ya, 2000, no. 4, pp. 39–47. (in Russ.).

Tarasevich B.N. IK-spektry osnovnykh klassov organicheskikh soyedineniy. Spravochnyye materialy. [IR spectra of the main classes of organic compounds. Reference materials]. Moscow, 2012, 54 p. (in Russ.).

Stojanović Ž., Jeremić K., Jovanović S., Lechner M. Starch, 2005, vol. 57, pp. 79–83. https://doi.org/10.1002/star.200400342.

Kolosov P.V., Bazarnova N.G., Markin V.I. Vysokomolekulyarnyye produkty karboksimetilirovaniya rastitel'nogo sy-r'ya s sorbtsionnymi svoystvami. [High-molecular products of carboxymethylation of plant raw materials with sorption properties]. Barnaul, 2014, 134 p. (in Russ.).

Sorokin A.V., Goncharova S.S., Lavlinskaya M.S., Holyavka M.G., Faizullin D.A., Zuev Y.F., Kondratyev M.S., Artyukhov V.G. International Journal of Molecular Sciences, 2023, vol. 24, 11246. https://doi.org/10.3390/ijms241411246.

Peppas N., Brannon-Peppas L. Journal of Food Engineering, 1994, vol. 22, pp. 189–210. https://doi.org/10.1016/0260-8774(94)90030-2.

Copyright (c) 2025 chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.