THE INFLUENCE OF THE CIRCUMFERENTIAL ROTATION SPEED OF A MOVABLE BARRIER DURING HYDRODYNAMIC ACTION ON INDUSTRIAL HEMP

UDC 676.157

Abstract

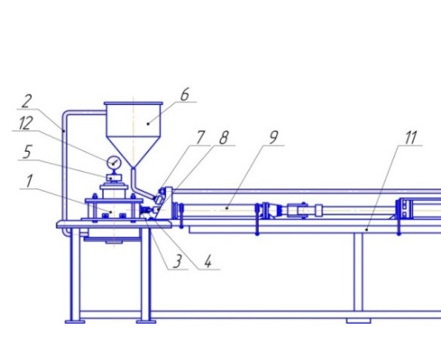

The work is devoted to the study of the hydrodynamic grinding of industrial hemp in a "jet-barrier" type plant in order to optimize the process for the production of paper products. The purpose of the study is to determine the influence of the circumferential rotation speed of a movable barrier and its structure on the paper-forming properties of a fibrous semi-finished product and the physico-mechanical properties of the finished product. The effect of the rotational speed (900 and 2000 rpm) and the number of turbine blades (12 and 24) on the Shopper-Rigger grinding degree, water retention capacity, breaking length and penetration resistance has been experimentally studied. It has been found that an increase in the grinding time leads to an increase in the degree of grinding, and the nature of the dependences of water retention, breaking length and penetration resistance on the variable parameters varies significantly. Various types of dependencies (linear, parabolic, and inversely parabolic) have been identified, indicating the complex nature of the influence of hydrodynamic factors on fiber properties. The results obtained make it possible to identify trends for determining the optimal grinding modes of industrial hemp in order to achieve the necessary characteristics of paper products.

Downloads

References

Korda Zh., Libnar Z., Prokop Yu. Razmol bumazhnoy massy. [Paper pulp grinding]. Moscow, 1967, 421 p. (in Russ.).

Alashkevich Yu.D. Osnovy teorii gidrodinamicheskoy obrabotki voloknistykh materialov v razmol'nykh mashinakh: dis. … dokt. tekhn. nauk. [Fundamentals of the theory of hydrodynamic processing of fibrous materials in grinding ma-chines: diss. … Doctor of Technical Sciences]. Krasnoyarsk, 1987, 361 p. (in Russ.).

Marchenko R.A. Intensifikatsiya beznozhevogo razmola voloknistykh polufabrikatov v tsellyulozno-bumazhnom proizvodstve: diss. … kand. tekhn. nauk. [Intensification of knifeless grinding of fibrous semi-finished products in pulp and paper production: diss. … Cand. of Technical Sciences]. Krasnoyarsk, 2016, 161 p. (in Russ.).

Yerofeyeva A.A. Beznozhevoy razmol voloknistykh polufabrikatov s uchetom reologicheskikh osobennostey suspenziy: diss. ... kand. tekhn. nauk. [Knifeless grinding of fibrous semi-finished products taking into account the rheological properties of suspensions: diss. ... Cand. of Technical Sciences]. Krasnoyarsk, 2012, 134 p. (in Russ.).

Kutovaya L.V. Kompleksnyy parametr protsessa obrabotki voloknistykh suspenziy beznozhevym sposobom v ustanovke tipa "Struya-Pregrada": avtoref. diss. … kand. tekhn. nauk. [Complex parameter of the process of pro-cessing fibrous suspensions by a knifeless method in a "Struya-Pregrada" type installation: author's abstract. diss. … candidate of technical sciences]. Krasnoyarsk, 1998, 20 p. (in Russ.).

Litvinova M.M., Alashkevich Yu.D., Marchenko R.A. Khvoynyye boreal'nyye zony, 2024, vol. 42, no. 3, pp. 29–38. https://doi.org/10/53374/1993-0135-2024-2-88-94. (in Russ.).

Franc J.-P., Michel J.-M. Fundamentals of Cavitation. Dordrecht: Kluwer Academic Publishers, 2005, 306 p. https://doi.org/10.1007/1-4020-2233-6.

Brennen C.E. Cavitation and Bubble Dynamics. Oxford University Press, 1995. https://doi.org/10.1093/oso/9780195094091.001.0001.

Redlinger-Pohn J.D., Petkovšek M., Gordeyeva K., Zupanc M., Gordeeva A., Zhang Q., Dular M., Söderberg L.D. Biomacromolecules, 2022, vol. 23(3), pp. 847–862. https://doi.org/10.1021/acs.biomac.1c01309.

Li T., Chen C., Brozena A.H., Zhu J.Y., Xu L., Driemeier C., Dai J., Rojas O.J., Isogai A., Wagberg L., Hu L. Nature, 2021, vol. 590, pp. 47–56. https://doi.org/10.1038/s41586-020-03167-7.

Likhodeyevskiy A.V. Teoriya i praktika mirovoy nauki, 2021, no. 3, pp. 29–38. (in Russ.).

Desanlis F., Cerruti N., Warner P. Hemp: Industrial Production and Uses. CAB International: Wallingford, UK; Bos-ton, MA, USA, 2013, pp. 98–124. https://doi.org/10.1079/9781845937935.0098.

Rijavec T., Janji´c S., Aˇcko D.K. Tekstilec, 2017, vol. 60, pp. 36–48. https://doi.org/10.14502/Tekstilec2017.60.36-48.

Viskovi´c J., Zheljazkov V.D., Sikora V., Noller J., Latkovi´c D., Ocamb C.M., Koren A. Agronomy, 2023, vol. 13, 931. https://doi.org/10.3390/agronomy13030931.

Salmén L. Plant Biomechanics: From Structure to Function at Multiple Scales. Springer International Publishing: Cham, 2018, pp. 3–19. https://doi.org/10.1007/978-3-319-79099-2_1.

Mittal V., Panghal A., Gupta R. Harvesting Food from Weeds, 2023, pp. 143–181. https://doi.org/10.1002/9781119793007.ch5.

Litvinova M.M., Alashkevich Yu.D., Marchenko R.A., Savenkov S.S. Khvoynyye boreal'noy zony, 2024, vol. 42, no. 5, pp. 61–65. https://doi.org/10.53374/1993-0135-2024-5-61-65. (in Russ.).

Patent 2363792 C1 (RU). 10.08.2009. (in Russ.).

Karelina A.A., Alashkevich Yu.D., Kozhukhov V.A. Lesa Rossii: politika, promyshlennost', nauka, obrazova-niye: materialy VII Vserossiyskoy nauchno-tekhnicheskoy konferentsii. [Forests of Russia: policy, industry, science, educa-tion: materials of the VII All-Russian scientific and technical conference]. St. Petersburg, 2022, pp. 176–179. (in Russ.).

Copyright (c) 2025 Chemistry of plant raw material

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.